XPowa

Go beyond sweeping

With a high capacity vacuum sweeper and a high pressure washer the sweepers from Bucher's specialist range can adapt to your exact needs and application. The brush gear and spraybars make sure you get the job done flawlessly.

Get to know the Bucher XPowa

Sweep, vacuum and wash to return even the most soiled surfaces ‘back to black’. A 14m3 waste capacity is combined with powerful vacuum and high pressure washing for use on roads, mines and all nature of industrial site. Detergent system and surface scrapers can be added for particularly arduous conditions,

Deep clean roads, streets and industrial sites with a large selection of brush gear and the power of a water pressure system. Do more and better with one sweeper.

Clean anything from pedestrian areas to streets, roads and industrial sites. This high capacity sweeper is up for any challenge. With a hopper size up to 14 m3, a high capacity fan and adaptable brush gear, you are sure to meet any demanding job.

A large hopper with up to 14 m3 capacity maximizes your sweeping time improving your overall productivity.

Key specifications

Up to 14 m³ hopper capacity

Up to on 4 axle chassis

Air flow up to 520 m³/min

High pressure wash systems 150 - 400 bar

Spraybars on all brush systems

Wide suction and rotor cleaner options

Up to 300 mm suction hose

Optional equipment

Specialized sweeping gear for all environments

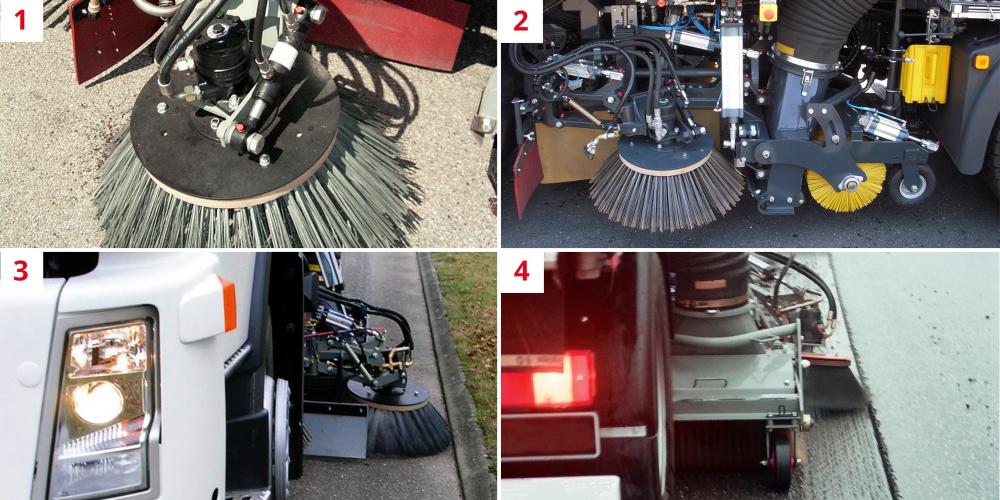

Sweepgear systems remove debris from a road or other surface and direct this into high capacity vacuum nozzles. The XPowa has multiple sweep options to suit all applications - some located between the truck axles, or side sliding to add sweeping width, or in front of the vehicle to clean debris before it is compacted by the truck’s tyres. These combine to maximise performance and productivity.

1. Rotatilt, right and / or left hand channel brush

2. Multi coupling, right and / or left hand side

3. Brush unit, side sliding, right and / or left

4. Brush unit, side-sliding, right or left - 400 mm (with WSB)

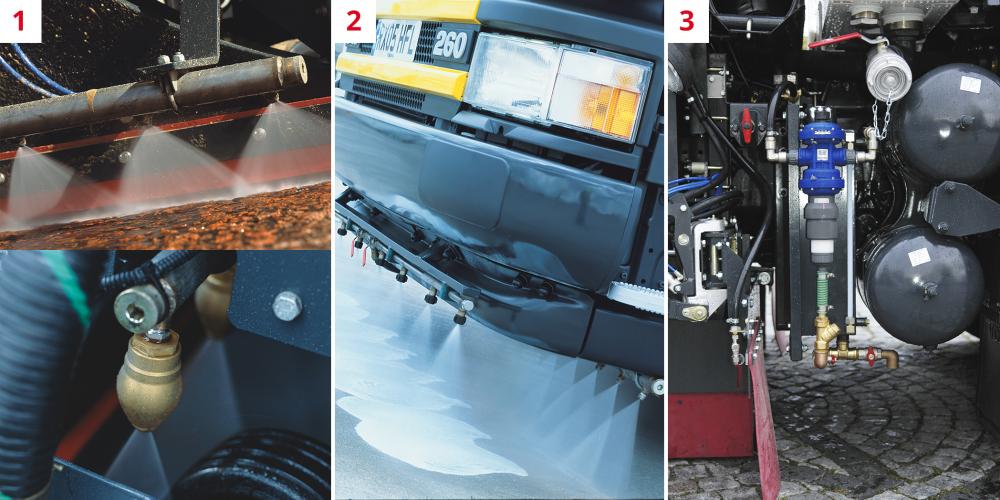

Impressive high pressure systems up to 400 bar

High pressure water systems are available to suit all applications. Spray bars can be located in any position – front, mid mounted, rear mounted or situated near to suction nozzles or brushes as needed. Performance ranges from 150 bar and 80 litres/min up to 400 bar and 100 litres/min. Key options:

1. Water pumps

2. Detergent systems

3. Nozzles to suit - pencil jet, rotating jet or full rotor jet systems

Increase your water capacity significantly

As standard, water tanks are situated on each side of the hopper to give a low centre of gravity and vehicle stability. Additional water may needed when longer sweeping time is required or where access to fresh water is limited or when large quantities of water are required. The range encompass both additional water tanks and in hopper water tanks.

1. Additional water tank between cab & hopper

Made of stainless steel and located between the cab and hopper, linked to the standard tank. Choose from 1100, 1500 or 2000 liters capacity.

2. In hopper water tank

Made of stainless steel and linked to both the standard tanks on each side of the hopper to maintain equal balance of the vehicle as the water is consumed.

Simple solutions for demanding sweeping tasks

1. Front brush: Prevent planed asphalt from being crushed back into the surface by the vehicles front tyre.

2. Front brush, side sliding - 750mm: For asphalt planning, surface preparation, V-channel and lay-by cleaning and an extra reach of the side sliding arm allowing the vehicle to sweep where it normally would be inaccessible. *Available with a hydraulic tilt.

3. Front brush, side sliding - 300mm: Allowing the operator to place the brush right into the curb and road surface, and can also be used to prevent the tire compacting debris into the surface. *Available with tilt, to brush onto a curb top.

4. Front brush, ø1100mm, side sliding - 1100mm: Provides a big advantage when sweeping lay-bys, bus stops, along roads with overhanging trees and when sweeping tunnels.

5. Brush behind front wheel: For the removal of weeds and grass that is growing at the edge of the road or on top of curbstones. Height control enables the brush to remove the weeds without the use of harmful chemicals.

Accessories, gully clearing and remote litter collection

1. Scrapers: Full width scraper, mounted behind front wheel or scraper behind right and/or left hand front wheel.

2. Magnets: Rear or front-mounted magnet for carrying out high-speed runway clearing or roadside cleaning.

3. Edge Cutter behind right and/or left hand front wheel: Ideal for cutting back the edge of the road as is encroaches over time. The edge cutter removes the grass, weeds and earth in preparation for re-surfacing or just for cutting the edge back to the asphalt edge.

4. Top- or rear mounted wander hoses: The wander hose options provide the operator with easy to handle gully sucking apparatus, which can be used to pick up litter or empty sand traps as well as gully clearing.

No more trails of water

Special side suction nozzles for use with rear mounted wide suction

With most high pressure water jetting systems, the risk of water spilling sideways and so leaving a trail of water behind the vehicle increases as the water pressure rises. With the special side suction nozzles, this risk is virtually eliminated since the nozzles are mounted on the outermost edges of the wide suction. With the addition of the side suction nozzles, an extra side curtain prevents some of the side spillage and the special side suction nozzles suck it up into the hopper. The special nozzles (one on each side) are activated at the same time as the rear suction so there is no need to activate any special flaps.

Get to know more

Exceptional performance with minimum noise and fuel consumption

Choose between a twin engine with either a standard or a high capacity fan where power transmission is done via a belt drive system and fluid flywheel. For ultimate speed control and powering the entire sweeper and washer functions choose instead having a single engine (from the chassis) with hydrostatic transmission and high capacity fan.

Superior results with less water

As an alternative to full width rear suction and spray bars, Bucher offers a rear mounted rotor cleaning system. It operates at 60 to 80 litres per minute compared to the traditional 100 litres per minute. This reduces the costs of fuel, waste disposal, refilling and allows for better utilisation (more on-station time). This system is equally valuable when used in road maintenance, construction, industrial site cleaning, and aircraft parking stand cleaning.

The system is rear mounted, it uses 4 rotating spray bars covering the full width of the truck and full width suction. It is completely enclosed ensuring no water seepage and a high vacuum that collects all water and waste. It can be used with a range of high pressure pumps from 100 to 400 bar.

Efficient oil/ degreasing removal

Detergent system options for grease and oil spill removal combined with a high pressure system. Front mounted detergent spray bar for stand-alone dispersal. Variable dosing system to control the dilution of the detergent by mixing with water. There are two different detergent systems available: mixer or mixed.

In cab control systems

The sweeping controls are located in the cab. You have the opportunity to choose between a standard orintegrated control system, which gives you a more flexible control system, to accommodate your needs and requirements.

Flexible hopper and chassis sizes for a custom set up

2 axle 9 m³ hopper, 3 axle 12 or 14 m³ hopper, 4 axle 14 m³ liter hopper

Product variations

Bucher XPowa V90

Ideal for the city center

A small but powerful unit with a large capacity hopper. The 9 m³ stainless steel hopper is designed to outperform in street and pedestrian zones cleaning within urban and residential areas. Available with a twin or hydrostatic engine.

Bucher XPowa V120

Cleaning made easy

Flexibility and performance with a medium-sized truck-mounted sweeper. The 12 m³ stainless steel hopper is perfect to take on a wide variety of jobs.

Available with a twin or hydrostatic engine.

Bucher XPowa V140

For demanding cleaning

The larger capacity makes it ideal for more challenging jobs. More room to carry more water and to accommodate a heavy duty brush gear configuration. Available with a twin or hydrostatic engine.

Other special truck mounted sweepers

Discover Bucher Municipal

Find out why Bucher Municipal is the perfect partner for you.

Buy our products

and services

Providing products and services

around the world.