UniQa H

The pioneering spreader built around the customers needs

Automatic spreader for heavy trucks, from 4m³ to 16m³.

UniQa represents the experience of 60 years of innovation in winter maintenance and it aims to offer the best possible operative conditions for each customer specific requirements.

UniQa incorporates all the characteristics a winter maintenance spreader requires such as consistency and precision regardless of salt quality, salt storage method or environment temperature, a smart control system, customisable modular design, cost-effectiveness over time as well as long lifetime expectancy thanks to quality manufacturing and materials.

Get to know the UniQa spreader

The large number of solid and liquid capacity combination allows it to fit every kind of heavy truck, always with the correct solid to liquid ratio and a balanced axle load distribution.

Furthermore, UniQa is perfect for road sanding, de-icing or anti-icing winter maintenance application. In fact UniQa can be configured to apply all kinds of spreading material, from pure sand to pure brine, accordingly to your techniques. The driving system can be customised to meet the requirements of a dedicated winter truck or of a standard transport truck.

The smart control system can be implemented over time with automated functions offering a step-by-step upgrade and a great resale value.

Three different demounting systems and our custom built sub-frames complete the comprehensive offer, delivering outstanding flexibility in personalisation.

A large use of stainless steel and durable polyethylene components ensures high protection degree over its entire lifespan while reducing maintenance costs. To further extend the corrosion protection, all steel and stainless steel assembly are shot blasted and powder-coated with a specific double layer treatment or galvanised.

The ends of the hydraulic pipes and couplings are protected with a special wax, while hydraulic valves, motors, and mechanical gearboxes—subject to heat expansion—are treated with a specialized painting process to ensure both protection and flexibility.

The UniQa chain conveyor is designed to last the entire life of the spreader requiring minimal maintenance over time.

The all welded drive shaft, through the parallel driving sprocket, ensure a linear and synchronous advancement of the chain hence avoids any side deviation which can occur on the conveyor belt.

To help maintenance process we also deliver as standard a centralised greasing system allowing to reach all the stainless steel bearings from one easy-access greasing point.

Whenever possible, consumable parts are designed to minimize maintenance costs by allowing only the worn components to be replaced, rather than the entire assembly.

We believe in a sustainable growth of our generation, permitting the future generation to fulfil its needs without restriction. In fact more than 90% of UniQa weight can be recycled and some of its components are made of recycled materials too.

The most accurate spreading pattern available on the market combined with the highly automated functions optimise the spreading material application, reducing costs and environment pollution.

At our production facility, we are deeply committed to environmental responsibility. Our sites are ISO 14001 certified, and for many years, our paint shop has utilized a powder recovery system that recycles and reuses primer, significantly reducing resource waste.

Additionally, our energy consumption is sourced from our photovoltaic system and a certified renewable energy supplier, reflecting our commitment to a cleaner, more sustainable world.

Key specifications

Large chain conveyor,

immune from bridge effectModern painting process

guarantees higher resistance

and lower maintenance costsVersatile configurability

on the base of customer needsThe roller breaker allows constant

and homogeneous flow to the discSuitable for all spreading technique,

from sand only to pure brineIntuitive control panel interface

Autonomous spreading operations

with Bucher Assist

Key Features

Regardless of salt quality, salt storage method or environment temperature the UniQa chain conveyor ensure consistency, precision and it is immune from the bridge effect.

The most spotted spreading material tends to compact in presence of high humidity and low temperature as its intrinsic physical property. In this scenario every small gap or low inclined surface is an anchor point to create a solid bridge into the hopper and stop the salt from flowing on the conveyor. In case this "bridge effect" occurs it is necessary to manually break all the material compacted inside the hopper with high economic costs, safety issues and the problem connected to an unexpected stop during snowfall.

The Bucher chain conveyor is really wide, almost double the size of the other systems, therefore the hopper has virtually vertical sidewalls. Moreover the chain concept lets the material lay down on the hopper bottom and not on the conveyor requiring only a minimal lightening plate. Vertical sidewalls combined with a small lightening plate create a spacious area for the material, completely preventing bridge formation and ensuring a consistent, free flow to the disc.

This unique conveyor system offers an additional advantage: its wide transport width allows the conveyor to operate at low speeds, requiring minimal power while delivering high starting torque. Unlike auger conveyors, there’s never a need to manually move the chain before starting the equipment—even if it has been left fully loaded outdoors for several days.

Ready for any anti-icing or de-icing task

The design of UniQa allows it to be equipped to any kind of heavy truck thanks to a variety of solid/liquid capacity combination. 12 different hopper sizes and many combinations of lateral and additional front tanks allows us to achieve the capacity the customer requires while maintaining a perfect truck axle load distribution. With the application clear in mind UniQa is engineered to fulfil any anti-icing or de-icing task, being capable of delivering from pure sand, to adjustable ratio pre-wetted salt and even pure brine by disc.

Four different spreading groups, dedicated to different spreading materials, ensure a perfect spreading pattern, high protection from blocking and great reliability.

All our spreading groups features the disc feeding chute in polyethylene, completely closed and with rounded shape. This combination ensures supreme material flowing thanks to the polyethylene slippery characteristic and, being closed, avoids humidity and cold air raised from the truck to negatively affect its slipperiness. LED light, road approved signalisation, fully corrosion resistant tarpaulin cover and a hot galvanised screening grid completes the most spotted configurations.

UniQa control system make the complex easy

Stick to operational procedure whilst driving in the worst conditions possible and also respecting the environment is a challenging task.

EcoSat10 control system is specifically designed by Bucher with a practical and operator-orientated conception to help achieving this challenge. The easy-to-use interface includes a large 7” colour display, 3 programmable encoder and 7 smart buttons enabling a comfortable and trouble-free use.

While working EcoSat10 automatically denied the operation which cannot be done in the actual condition and, together with its functional design, allows the driver to be focused on driving and not continuously looking at the control panel screen.

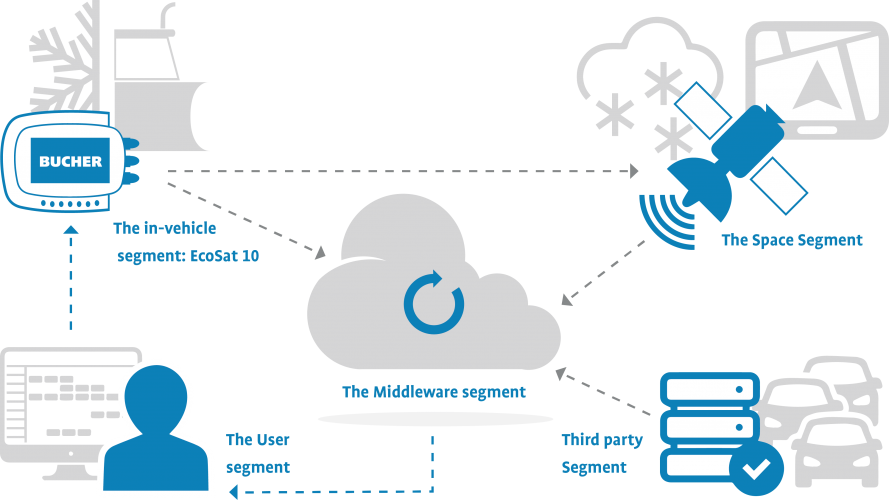

The EcoSat10 smart conception combines in a single device a powerful, micro-processor based, control panel, a data transmission module and a complete satellite navigation system as an option.

A multilevel password system protects the system from unexpected parameter modification and the driver identification ensures the complete control of the spreading operation even if one spreader is used on three-shift working by several operators for prolonged snow falls.

Adaptable to every kind of heavy truck

UniQa is moved by a powerful hydraulic system which can be powered from the truck hydraulics or by an on-board auxiliary engine, to fit both standard transport truck and dedicated winter maintenance truck.

The UniQa powered by the truck hydraulics conform to European standard ensuring performance and adaptability between different vehicles.

Load sensing hydraulic systems are becoming more and more popular for multi-purpose trucks and we are ready for it.

The on-board auxiliary engine is designed to guarantee the maximum efficiency thanks to an automatic acceleration based on energy consumption. This allows the engine to start on low RPM and then accelerate as or when required, saving precious fuel over the long life of the spreader.

The demounting option includes the most classic handle telescopic supporting feet and the automatic tipper system available in two version for empty or fully charged spreader.

The hopper is a self-supporting frame which doesn't need additional sub-frames for fully charged demounting system reflecting the robust design of this machine.

The truth about the roller breaker

Narrow conveyor systems need a device inside the hopper to try preventing the bridging effect by constantly moving the material. This device acts as an agitator and sometimes is mistakenly called a roller breaker.

The UniQa chain conveyor is immune from the bridge effect hence it doesn't need an agitator. The intention of the UniQa true roller breaker is to guarantee a constant and homogenous material flow to the disc.

The UniQa system avoids the flow pulsation regardless of salt quality, salt storage method or environment temperature ensuring a perfect material distribution over the entire spreading pattern. The true roller breaker is located transversally to the conveyor right above the disc in a closed compartment outside the hopper. It is fully hydraulic driven and, if necessary, it could absorb all the available power to break even the largest clumps. Moreover, it rotates in the opposite direction of the conveyor reducing the blockage possibilities and unexpected down-time. In the event of a blockage, only a small compartment needs to be emptied—unlike auger conveyors or dosing-gate systems, which require the entire hopper to be cleared.

Human machine cooperation for the best results

EcoSat10 can be customised adding features such as data logging, vehicle tracking and data transmission but also the complete automatisation of the spreading operation using the IRT05 thermal sensor and Assist. The data transmission module can be integrated directly into the control panel simplifying the cabin wiring installation and reducing the space necessary for additional device. Moreover, the integrated solution provides peace of mind when in use and doesn't need any configuration from the customer saving valuable time.

The Assist IRT05 allows the control box to acquire the road temperature. It can be used as a road contactless thermometer or to automate the dosage parameter accordingly to the real road conditions. Controlling the dosage function if required it can also be used to start/stop the spreading operation.

Assist RouteReplay technology is based on geo-referenced spreading parameter which are automatically operated by the spreader along the road.

With the EcoSat10 precision navigation system, the driver is guided along the route while the system simultaneously detects the vehicle’s position. This allows the control panel to automatically apply the correct pre-set parameters at all times.

Built to safely perform over its entire lifespan

Having the safest driving possible on slippery surface and low visibility should be one of the main concern for a winter equipment. For this purpose the conveyor and the hopper shape combination enable the lowest hopper profile and material centre of gravity compared to any other conveyor system, enhancing the stability of the vehicle.

The available automated functions even raise this safety level, in fact the driver isn’t obliged any more to look at the control panel screen when driving to know which function he has to operate thanks to Assist.

UniQa is completely immune to bridge effect, significantly reducing the risks associated with traditional spreaders—such as the need to enter the hopper to remove compacted salt and the unexpected downtime that can occur during road treatment.

Nearly all maintenance operations can be performed from the ground. Moving parts are protected by covers or safety sensors, ensuring operator safety at all times.

The spreading operation is controlled by a sensor on the disc in order to inform the driver if any blocks occur stopping the salt from being spread to the surface.

Get to know the UniQa Combi spreader

With the application clear in mind UniQa is engineered to fulfil any anti-icing or de-icing task, being capable of delivering from pure sand, to adjustable ratio pre-wetted salt and even pure brine by disc or multiple nozzle system.

Beside the brine delivery system this kit can be assembled to meet your specific requirements combining different size of additional tank, for an additional capacity up to 7.5m3 over the standard form.

The multiple nozzle system has proven its effectiveness over time and can spray up to 3 lanes in standard form.

The brine pumps are hydraulically driven, high performance gear pumps with specific design for highly corrosion material engineered by Bucher from its long experience.

The delivery system is completely automated and controlled from the control panel, which adjusts flow and control the valves accordingly to the parameter set from the driver for a total peace of mind while driving.

The nozzles are all in stainless steel and require only minimal cleaning over time ensuring full operation even in the worst conditions.

Conversely to jet nozzles commonly used in agricultural field, the fan nozzles ensure maximum precision in width and dosage application of brine.

This converts in saving materials, carry out a better job and, thanks to the mechanical action, it is the most effective de-icing method on ice or hard compacted snow layer.

Other spreaders

Discover Bucher Municipal

Find out why Bucher Municipal is the perfect partner for you.

Buy our products

and services

Providing products and services

around the world.