One

Spreader for medium and light trucks

Available in container sizes from 1.1m³ up to 5.0m³.

Bucher One metal belt spreader for light trucks, suitable for salt, sand or grit. The hopper, fully welded to prevent vibrations, is made in AISI 304 stainless steel, providing load capacity without any deformation.

Get to know the One spreader

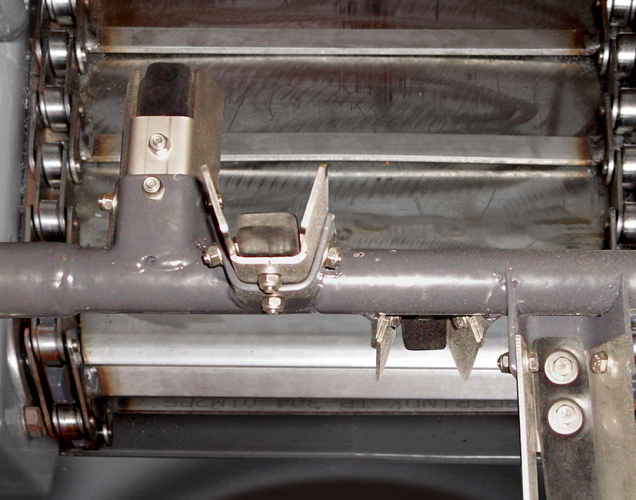

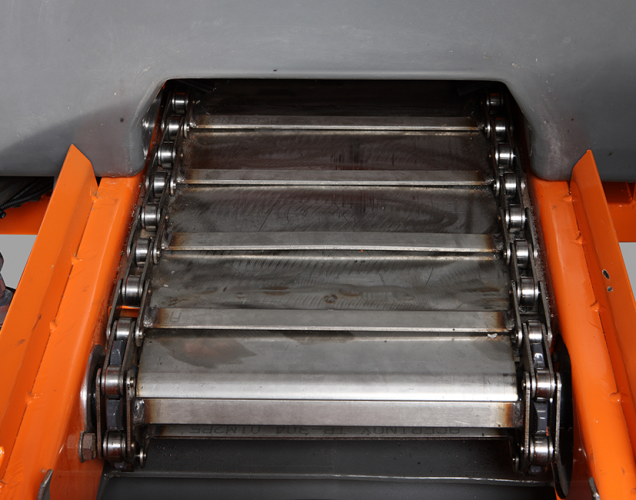

Metal belt: The feeding system is realised by an AISI 304 stainless steel chain with cross-bars. The chain is guided by toothed pinions that enables a constant traction maintaining a correct translation synchrony, without skidding.

Auger: The feeding system is realised by an auger with variable pitch turn. The bottom of the feeding system is realised by an anti-abrasive rubber to enable the passage of bigger lumps avoiding the auger blockage.

The gritting machines of the One range are renowned for their excellent reliability, first-class service and attractive price-performance ratio. The excellent equipment finish and the use of tried-and-tested components are further proof of the great technical expertise built into our machines.

The high proportion of stainless steel ensures even the basic amenities for a long lifetime of the spreaders (Skid plates, spreader disc, feet sockets and all fasteners are in stainless steel). The device security cover is also made of stainless material.

Key specifications

Large choice of container sizes

Low container profile

Low container centre of gravity

Very short overhang of spreader unit

Standard-compliant spreading precision test

Special paintwork and many stainless steel components

Key features

Roller breaker

A hydraulically driven roller breaker with stainless steel blades is installed on the exit side of the chain or belt feeding system. The roller breaker comes as an option with the auger feeding system and is placed lengthways. The roller breaker allows material to flow continuously from the hopper to the spreading unit, breaking down any lumps and preventing them from dropping in an uncontrolled way.

Metal belt

The feeding system is realised by metal belt an AISI 304 stainless steel with cross-bars. The chain is guided by toothed pinions that enable a constant traction, maintaining a correct translation synchrony, without skidding.

“Light” gritting system

“Standard” spreading unit with 470mm disc and all metal parts made of AISI 304 stainless steel. With asymmetry that can be adjusted to five different positions, it can spread material up to a width of 8m. When being moved, it can be easily lifted and turned over and a sensor ensures that the plate is automatically blocked when it is lifted.

“Premium” gritting system

Spreading unit with large disc (600mm diameter) and all metal parts made of AISI 304 stainless steel. With asymmetry that can be electrically adjusted to five different positions, it can spread material up to a width of 12m. The spreading disc has 6 AISI 304 stainless steel blades offering total lasting protection against corrosion. The blades have variable geometry to adjust the spreading of the material to the particle size. The chute leading to the spreading disc is made of HD polyethylene with a circular cross-section, cast moulded to allow the salt to flow at low temperatures. When being moved, the entire unit can be easily lifted and turned over and a safety sensor ensures that the plate is automatically blocked when it is lifted.

Hydraulic Driving systems

Hydraulic system and compliant with the EN15431 European standard.

Auxiliary engine Driving systems (opt)

Driven by a 2-cylinder liquid-cooled diesel engine.

Wetting device (opt)

The wetting device has a volumetric pump directly flanged to the hydraulic motor which is maintenance free. The nitrile rotor only requires internal washing at the end of the season. The side tanks are made of sturdy, light-weight rotomoulded polyethylene which is completely recyclable. The solid/liquid ratio is electronically controlled from the control panel in the driver’s cab.

Get to know more

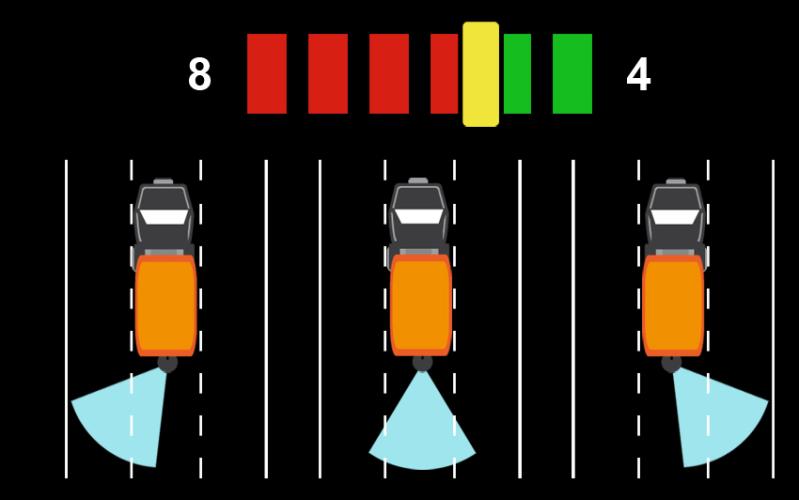

Latest generation microprocessor control systems for all kind of spreaders, with maximum flexibility in programming and visualising the different spreading parameters: width, asymmetry and dosage depending on the vehicle speed. Six different tools in all-in-one control box.

Ecosat has an integrated GSM/GPRS module (optional) which enables operational data transmission. In case of bad coverage (e.g. tunnels) the data is logged and will be transmitted as soon as the connection is back.

Ecosat integrates (option) a multi-constellation GNSS receiver which supports GPS or GLONASS improving the localisation performance in terms of accuracy, continuity, availability, and reliability.

The Ecosat stores daily operational reports and global counters which can be downloaded or printed via serial connection.

A serial connection between the infrared sensor and the Ecosat allows automatic changing of the spreading dosage based on the road temperature.

The Route-Replay is based on pre-defined geo-referenced spreading parameters settings uploaded on the EcoSat before the operation and used automatically during the mission relying on an enhanced positioning. The driver is guided by means of vocal and visual messages which show the road section already treated as well as the section that still has to be done. It is possible to exit from any pre-set route and re-entry at any point along the section.

On spreaders with electrical control of asymmetry, this function provides full control of the direction of spreading. The screen display varies according to the type of asymmetry: with or without feedback. 5 pre-set positions can be selected.

In this section of the working area, it is possible to monitor the level material in the tanks, the solid quantity in the hopper and also the fuel level (only for equipment with auxiliary engine).

The vehicle speed can be simulated from 5 to 90Km/h in steps of 5. This feature is useful when there is no tachometer connection, when the connection is damaged or when the spreader has to work while the vehicle is not moving.

Other spreaders

Discover Bucher Municipal

Find out why Bucher Municipal is the perfect partner for you.

Buy our products

and services

Providing products and services

around the world.