Bucher UniQa He

The first heavy-duty

chain spreader that is 100% electric

For medium-sized and heavy trucks.

UniQa He is the first professional spreader that is 100% electric and represents our commitment to a sustainable future.

The great challenge was to develop a green solution keeping the highest performance typical of Bucher municipal products; the result is revolutionary equipment able to comply with the strictest market requirements, with no compromises on performance, and to raise the standard to a higher level. The UniQa of all time, but 100% sustainable.

Get to know the UniQa He spreader

UniQa He doesn’t require any special modification to the truck, offering a simplest fleet management!

The carrier vehicle requires no modifications, as this equipment operates without the need for connections to the truck or a control box. It’s a true "plug-and-play" solution that can be mounted on any truck with sufficient load capacity—eliminating all costs typically associated with vehicle installation and integration. The control system is engineered for maximum tuning precision, ensuring exceptionally accurate spreading operations. Besides, using a standard truck, it is possible to rent the vehicle just for the necessary time.

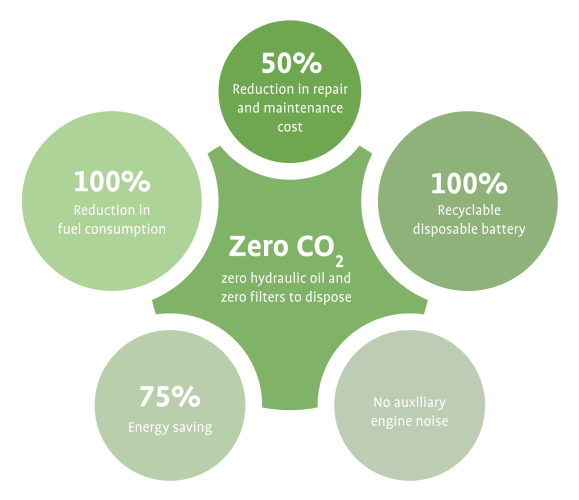

What makes UniQa He very special is the sustainability both in terms of environment/noise pollution and cost saving over time.

UniQa He is a lot quieter compared to traditional solutions, zero impact and it needs minimum maintenance during its lifetime.

This solution is particularly well-suited for urban environments, where noise and emissions reduction are top priorities. At the same time, it offers users the lowest possible life-cycle cost. The spreader features a high-efficiency 48V electric system that replaces traditional hydraulics, powered by a lithium battery and equipped with brushless motors and integrated inverters for optimal performance. This solution avoids power losses and allows independent and proportional energy absorptions and management for each motor.

Moreover, the lithium technology allows the battery partial charge during the salt refilling operation, even if the battery is not flat.

Battery pack - Up to 9000 working hours expectation

The lithium battery is protected in a dedicated compartment, with easy access for maintenance. Its technology allows the partial charge. The battery is covered by a special overcoat that protects it against low temperatures granting the possibility to work to -20° C.

Innovative tool for the service responsible as well as for the driver.

This tool reduces the operator workload while allowing them to comply with operational procedures. Thanks to man-machine collaboration, improves winter road maintenance quality. Accessible from everywhere, using a simple internet connection; the tool used for winter services management are available through a single web portal. Real-time weather analysis, telemetric and road morphology studies offer to the service responsible all necessary data to create precise winter maintenance mission, anytime and anywhere.

Key specifications

Emission free, UniQa He is Eco-friendly and highly efficient

Reduction of the operator's workload

Reduction of truck installation costs

Lower operational costs

50% lower maintenance costs

Battery up to 9000 working hours expectation

Power system IP6k9k rating certified

Key Features

Electric system designed to perform fast repair interventions

Through the remote control and service friendly layout, it is possible to know which equipment needs maintenance, transforming unplanned stops to shorter and fewer planned service time, thus increasing service availability.

Power and high efficiency through an integrated inverter

The compact design of the electric motor with integrated inverter, allows for fine-tuning, while avoiding dispersion or interference making it suitable to be used in every field. Motor and inverter assembly certified IP67 ingress protection rating.

Lithium state-of-art technology

Latest technology maintenance-free lithium battery, allowing partial and fast charging cycles without damages and designed for up to 9000 working hours.

Battery management system with smart technology enabling real-time remote diagnosis, automatic temperature protection, automatic cell voltage balance. 48v low voltage electric system enables safe and easy service.

EcoSat Pro control system

Ecosat20 belongs to the latest generation of touch screen, microprocessor-based control systems, with maximum flexibility in programming and displaying the different parameters.

Integrates a satellite navigation module, which guides the driver with vocal and visual messages. Unique design with 7” color touch-screen display.

Winter service supported by space technology and the cloud

ASSIST enables cost-effective, flexible and efficient winter services thanks to its innovative tools for the service responsible as well as for the driver.

ASSIST reduces the operator workload while allowing them to comply with operational procedures, due to the man-machine collaboration, improving the winter road maintenance quality.

Accessible from everywhere, using a simple internet connection; all the tools used for winter services management are available through a single web portal.

Real-time weather analysis, telemetric and road morphology studies offer to the service responsible all necessary data to create precise winter maintenance missions, anytime and anywhere with the guarantee to carry out the exact planned procedure.

New painting process

Bucher Municipal offers a new process of painting for winter road maintenance products. The big innovation is the application of a catalyzed liquid epoxy primer with a high zinc content. Compared to classic painting methods, the liquid primer provides greater protection to the finished product due to its elastic properties and ability to reach even the most difficult to treat spots.

Drive efficiency and reliability with our cutting-edge steel chain solutions

The system consists of a wide steel metal belt with high-strength cross bars. The chain of Bucher Municipal salt spreaders is composed of multiple metal alloys with specific properties to ensure efficiency throughout the life of the spreader. The metal belt is driven by sprockets that maintain constant traction and proper timing without slippage.

Spreading automation

Winter maintenance operators are helped by an automated system, able to adjust autonomously each spreading parameter. This means that the equipment always applies the exact dosage with the right pattern.

The on-board unit includes an accurate GPS navigation system able to guide the operator with visual and vocal messages.

Automated spreading combined with satellite navigation, results in economic use of de-icing materials, the best winter maintenance operations with any level of driver skills while reducing their workload.

Bucher ASSIST

An increasingly efficient fleet! Make your spreader smart and control spreading remotely with Bucher Assist.

Learn more Discover

Bucher UniQa H

The well-known Bucher UniQa with hydraulic drive or auxiliary motor.

LEARN MORE

Other spreaders

Discover Bucher Municipal

Find out why Bucher Municipal is the perfect partner for you.

Buy our products

and services

Providing products and services

around the world.