Husky L

High-value city sprayers for narrow track vehicles

Brine tank capacity from 500 litres up to 2,100 litres

The city sprayers of the Husky L range have an optimised container design which makes them ideal for mounting on a wide variety of municipal carrier vehicles.

The Husky L range of spraying units are intended purely for spreading brine. The brine tank is made of HD-PE (High Density PolyEthylene) with a wall thickness of 10mm. The brine is precisely metered by the Husky L spreader unit on to the spreader disc to be spread across a width of 6 metres.

Get to know the Husky L spreader

The new ECO pre-wetted salt technology from Bucher Municipal creates significant advantages in terms of economy. The low sidewall height of the Husky L range ensures that the driver has perfect, all round visibility. The low centre of gravity ensures safe driving and handling characteristics even in extreme conditions.

The gritting machines of the Husky L range are renowned for their excellent reliability, first-class service and attractive price-performance ratio. The excellent equipment finish and the use of tried-and-tested components are further proof of the great technical expertise built into our machines.

The high proportion of stainless steel ensures that even the basic components—such as the spreader unit holder, spreader disc, and all fasteners—have a long service life. The plastic gear pump is also long-life and low-maintenance.

Key specifications

Various sizes of brine tank available

Low container profile

Low container centre of gravity

Spreader unit can be swung up

Long-life, low-maintenance plastic gear pump

Unique brine spreader system – optimum spreading using a distribution disc

State-of-the-art liquid salt technology

High delivery rate from the brine pump

Key features

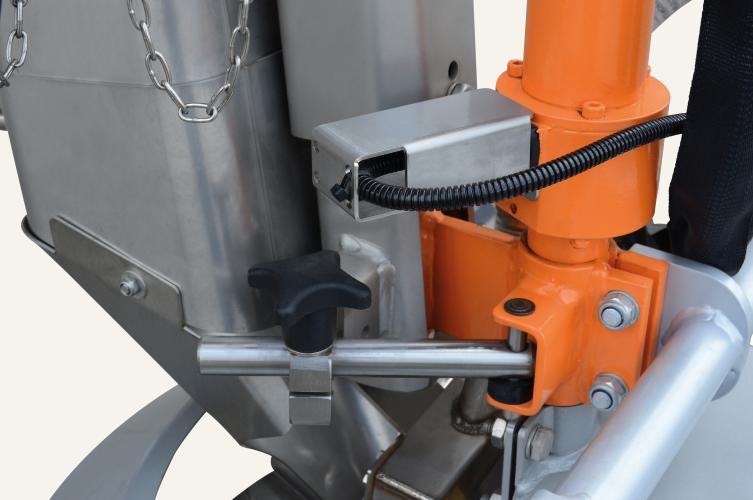

LED work light

The LED work light, positioned near the spreading unit, delivers bright white illumination across the work area. Its durable housing is both dust- and moisture-resistant

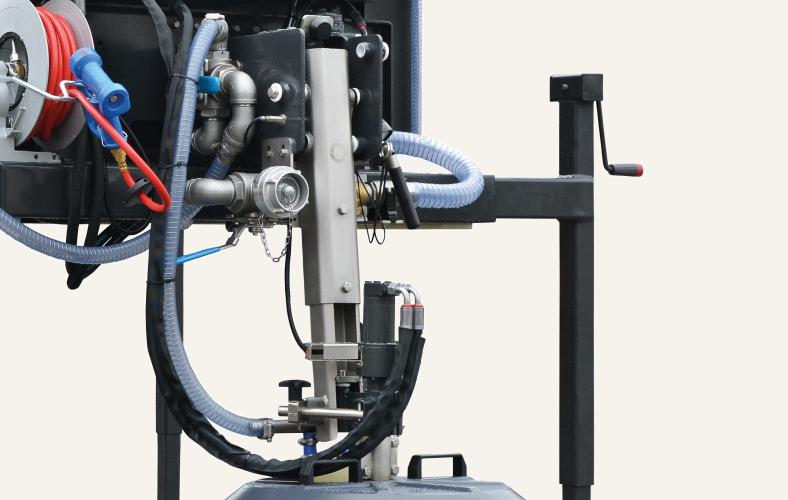

Mechanical demounting system (500kg) with hand crank

(standard) Optional mechanical or hydraulic demounting systems for setting down the loaded gritting machines are also available.

Liquid salt pump unit

The plastic gear pump delivers brine to the spreading disc efficiently and is designed for long life with minimal maintenance. The liquid salt pump unit has a high delivery rate (190ltr/min at 45ltr hydraulic oil).

Brine tank

The brine tank is made of HD-PE (High Density PolyEthylene) with a wall thickness of 10mm. The brine tanks are available in various sizes.

Rotary beacon (optional)

The rotary beacon is available upon request with a range of flashing and strobe lighting options.

Equipment box

The equipment box provides optimal protection for the hydraulic block, junction box, and black box. Constructed from steel and sealed against moisture, it ensures reliable performance in demanding conditions.

Spreader distributor

The spreader distributor applies brine evenly onto the road and features a stainless steel spreader disc with a specialized plastic cone and a durable plastic cover.

Control unit Ecosat (optional)

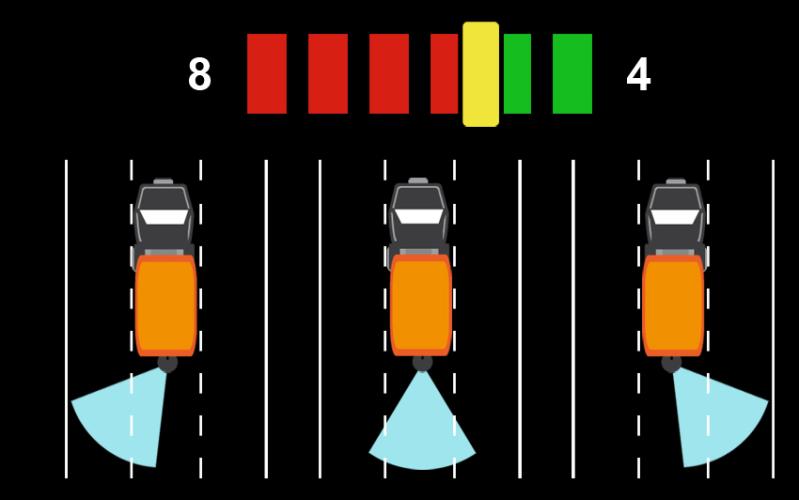

Latest generation microprocessor control systems for all kind of spreaders, with maximum flexibility in programming and visualising the different spreading parameters: width, asymmetry and dosage depending on the vehicle speed. Six different tools in all-in-one control box.

Electronic spread pattern programmer (optional)

A powerful servomotor and a potentiometer enable the symmetric and asymmetric setting of the spreading pattern with using the control panel. The servomotor is waterproof to IP 67 protection rating.

Sensor technology

Only available together with the Ecosat control panel. This compares the set-point and actual values of the spreader disc and the liquid salt pump. The sensors are sealed to IP 67 protection rating.

Swing-up spreader unit

For trailer operation, the spreader unit can be easily swung upward when mounted, with gas spring assistance ensuring smooth and effortless handling.

Pouring hose with hose reel (optional)

On request a pouring hose with hand spray gun and hose reel can be mounted.

Get to know more

The latest-generation microprocessor control systems are designed for all types of spreaders, offering maximum flexibility in programming and visualizing key spreading parameters—such as width, asymmetry, and dosage based on vehicle speed. Six different tools are integrated into a single, all-in-one control box.

Ecosat has an integrated GSM/GPRS module (option) which enables operational data transmission. In case of bad coverage (e.g. tunnels) the data is logged and will be transmitted as soon as the connection returns.

Ecosat integrates (optional) a multi-constellation GNSS receiver which supports GPS or GLONASS improving the localisation performance in terms of accuracy, continuity, availability, and reliability.

The Ecosat stores daily operational reports and global counters which can be downloaded or printed via serial connection.

A serial connection between the infrared sensor and the Ecosat allows automatic changing of the spreading dosage based on the road temperature.

The Route-Replay is based on pre-defined geo-referenced spreading parameters settings uploaded on the EcoSat before the operation and used automatically during the mission relying on an enhanced positioning. The driver is guided through vocal and visual messages, displaying both the treated road sections and those still to be covered. The system allows flexible routing—enabling the driver to exit a pre-set route and rejoin at any point along the section.

On spreaders with electrical control of asymmetry, this function provides full control of the direction of spreading. The screen display varies according to the type of asymmetry: with or without feedback. 5 pre-set positions can be selected.

In this section of the working area, it is possible to monitor the level material in the tanks, the solid quantity in the hopper and also the fuel level (only for equipment with auxiliary engine).

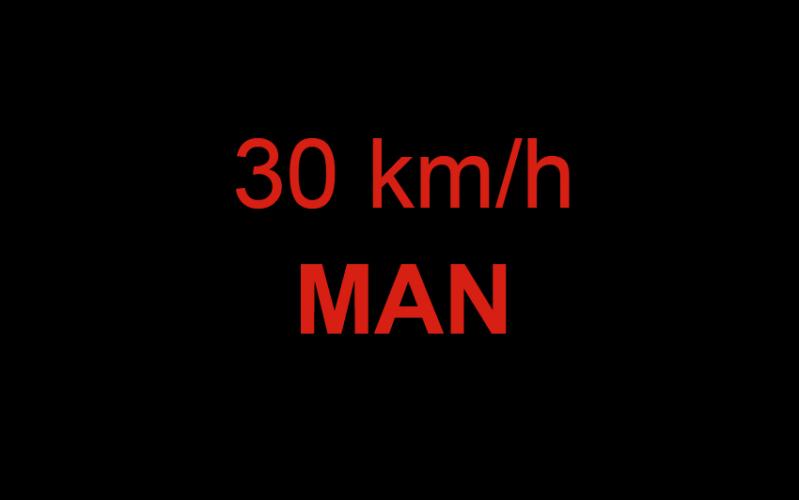

Vehicle speed can be simulated from 5 to 90 km/h in 5 km/h increments. This feature is especially useful when a tachometer connection is unavailable or damaged, or when the spreader needs to operate while the vehicle is stationary

The EcoTron control panel unit is characterised by its compact dimensions and high-resolution graphics display. The EcoTron performs sensor-based and monitoring of distance-dependent screw conveyor speeds and pump speeds, and also saves all relevant working data. A serial USB interface port is available for easy exporting of data.

Compact dimensions: Width 175 mm, Height 115 mm, Depth 65 mm.

Two rotary knobs with precise click-in positions.

Large colour display 95 mm x 55 mm, dimmable.

Enlarged display area if the quantity to be spread or the width of spread changes.

Simple and secure adjustment of the most important spreading parameters: Metering width and asymmetry.

Backlight function keys for secure operation of the main functions even under bad lighting conditions.

User-friendly control interface which presents all the important information in a clearly structured format - optimum design based the latest best practice.

Continuous recording all working data together with the overall information can be exported to an external storage medium (UBS stick) via the serial interface port.

Distance-dependent spreading by sensor-based monitoring of the screw conveyor speeds and pump speeds.

Other spreaders

Discover Bucher Municipal

Find out why Bucher Municipal is the perfect partner for you.

Buy our products

and services

Providing products and services

around the world.